Develop and make broadly available a robust, economically viable, shared-access platform for the technical development, manufacturing, and characterization of AAV-based gene therapy vectors. Ensure that workforce training for this platform can integrate into existing curriculum or training models to encourage adoption, and integrate improvements into the platform based on feedback from these training programs.

A gene-based therapeutics industry capable of serving patients across the full spectrum of unmet needs—from prevalent indications to ultra-rare diseases—that has access to high-quality viral vectors without cost or speed limitations.

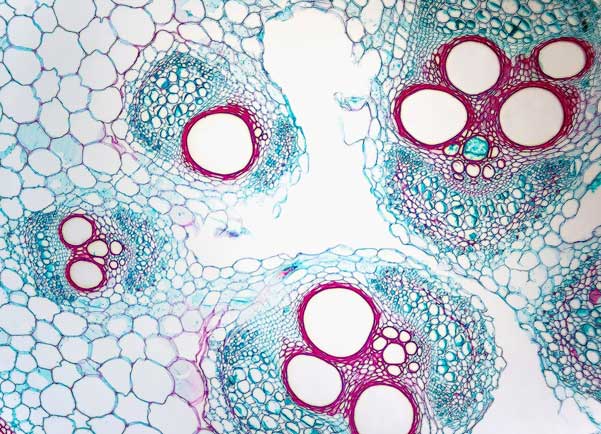

One of the most important vector platforms in use in the biopharmaceutical industry today is adeno-associated virus (AAV) vectors. Our Program focuses on advancing the manufacturing process and analytical capabilities for AAV vectors. The advances are critical for broad and rapid expansion of the emerging industry of gene-based therapeutics and ultimately the many patients and families who can benefit from access to these novel therapies.

NIIMBL is well-positioned to bring together the right resources to accelerate development of core manufacturing process platforms and essential analytical capabilities for viral vector product and process characterization, which can

The work of the program is organized around workstreams, topical focus areas.

Objective: Develop broadly available, robust, replicable, well-understood, and documented AAV manufacturing process.

Objective: Drive and demonstrate process capabilities enabling broad expansion of AAV gene therapy applications

Objective: Develop and disseminate AAV analytical capabilities for process and product characterization, batch release, and stability monitoring

Objective: Support availability and utilization of physical and documentary standards, reference materials, and data.

Alliance for Regenerative Medicine

AstraZeneca

Batavia Biosciences Inc

Bristol-Myers Squibb

Cytiva

Eli Lilly and Company

Federal Stakeholder: National Institute of Standards and Technology

Federal Stakeholder: Food and Drug Administration

Genentech

Joan & Sanford I. Weill Medical College of Cornell University

Landmark Bio

Lonza Biologics, Inc.

MilliporeSigma/EMD Serono

NIIMBL

North Carolina State University

Pfizer, Inc.

Sartorius Stedim

Spark Therapeutics, Inc.

United States Pharmacopeial Convention

University of Florida

University of Massachusetts Medical School

University of Massachusetts System

Virica Biotech Inc.

The program focuses on five key areas — standardization and contextualization, end-to-end automated control of critical quality attributes (CQAs), multivariate sensors and analytics, advanced control strategies, and bioprocess modeling and simulation – that will enable biomanufacturers to harness the power of data for real-time decision-making.

To access more program information, including:

Learn more about how being a member of NIIMBL can grant you and your company access to NIIMBL-led programs and other collaboration opportunities.